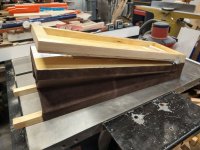

Im not quite here yet but i have a question about installing the leather. I understand the leather that surrounds the moveable board B which covers up the top and bottom hinge seams, but on the edges where the leather is folded over, how do you transition between this leather and the side wall bellow leather? is a little bit of the bellow leather glue (where the red lines show) enough to create a good enough seal to prevent air from escaping? Its mainly the back, the gap that the hinge barrel creates where there is no board to seal to that I am questioning. I know I probably over thinking something.

View attachment 114225