glenn bradley

Member

- Messages

- 11,557

- Location

- SoCal

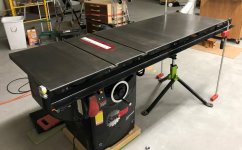

My first step in setting up a tablesaw is to assure it is in the right spot. Once all the hardware gets bolted on these things get a bit awkward to shift around. I go for level on tablesaw bodies before I add anything else. This gives me a reference point for everything that comes after.

For those who haven't done this a few times here is a method I use for putting on wings.

A piece of scrap a bit wider than the wing holds it roughly in place while you pinkie-tight the first few bolts. This assumes you put the fence rails on before the wings.

Once I have the left wing on and true I add the right.

I have enough cast iron sections to build out the side table area. I have done this on other saws and the increased mass is welcome. It will also solve the only bad thing I have ever had to say about the 3HP PCS Saw Stop; the side table is chintzy, made of too soft of a wood for the frame and is basically strong on "show" and weak on reliability.

.

.

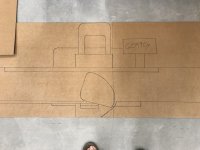

I posted earlier in this thread about my paper dolls for grown ups. They were definitely worth the little time they took to make.

.

.

For those who haven't done this a few times here is a method I use for putting on wings.

A piece of scrap a bit wider than the wing holds it roughly in place while you pinkie-tight the first few bolts. This assumes you put the fence rails on before the wings.

Once I have the left wing on and true I add the right.

I have enough cast iron sections to build out the side table area. I have done this on other saws and the increased mass is welcome. It will also solve the only bad thing I have ever had to say about the 3HP PCS Saw Stop; the side table is chintzy, made of too soft of a wood for the frame and is basically strong on "show" and weak on reliability.

.

.

I posted earlier in this thread about my paper dolls for grown ups. They were definitely worth the little time they took to make.

.

.

.

.