I'm getting it done, and getting very dirty and sweaty too! LOL

I got the flare unions installed to extend the lines to the new location. I'll leave them uncovered to check them for leaks later. (They are notorious for leaking).

When installing the unions I had a bit of a brain fart and used the old flare nuts, when I went to torque the old flare nut I broke it.

The new aircons operate at a much higher pressure needing the flare nuts torqued to a higher number, the old flare nuts are NOT up to this and this one broke, lesson relearned to not use old flare nuts. You can see how much beefier the new nut is on the right.

The inside unit is almost completely done. The drain is done too, only the electrical needs to be done, but I ran into a problem.

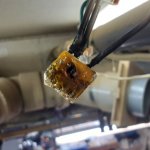

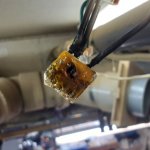

Crispy critters!

Holy let the smoke out Batman!

The workshop has it's own subpanel that's fed from the main panel on the first floor, but there were two existing circuits from the first floor main panel, in the workshop.

One that feeds four of the sixteen light fixtures I have and one fed four outlet boxes in the walls.

I like having four of the lights on the main panel upstairs so if I ever trip the main breaker on the subpanel I still have some lights.

I never used the outlets in the workshop from the upstairs main panel, so I had the aircon wired to that circuit.

The two first floor circuits come out in the same junction box in the ceiling. I decided to move the aircon to an open breaker I have on the workshop subpanel, as the aircon is much closer to the subpanel now, but I wanted to use the old surface mount box and outlet, no need to buy a new one.

When I opened the junction box I found this crispy critter...

WOW!

I thought it must be on the aircon circuit, but it was not, it's on the lighting circuit.

I turned off the breaker and cut the wires back to where the insulation was not burnt and replaced the connector.

I've got to run the new electrical line from the subpanel, and I have to then connect the line set to the outside compressor unit, and vacuum the lines down and check for leaks.

I reassemble the shelves and clamp rack. I also removed two old light fixtures and replaced them with two new LED fixtures. a lot of work to relocate the aircon, but even just finding that melted connection makes it worthwhile.

One more partial day to get the aircon done, then I'll have to cleanup workshop, because it looks like a bomb went off in here, but at least I'll be able to do that in a cool dry workshop.

Cheers

Priced a comparable unit at Menards for under $1,100. Worth trying to do it myself! Will be watching. Wondering how difficult the job might be.

Priced a comparable unit at Menards for under $1,100. Worth trying to do it myself! Will be watching. Wondering how difficult the job might be.