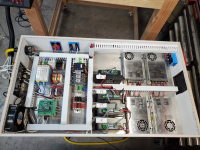

Made progress. All of the wiring seems to work but had a few setbacks.

The green button I'm using for engaging the contactor doesn't seem to work every time. Sometimes it does things right, sometimes not. Ordered new buttons just to be sure.

A couple of the power supplies also seem to be making a sound like frying bacon for about 15 seconds when the power is applied to them. They seem to be generating the right voltage, but the sound kind of un-nerves me a little bit. They seem to work fine on 110, but when I switch them to 220, they make the noise. No problem, I'll save them as backups and or repurpose them for something else I'll run on 110.

All items supposed to arrive monday. It's also finally gotten up to the upper 90's here, so I'll need to start doing my garage and outdoor work earlier in the day.

Might need to shift to the night shift like Vaughn, lol.