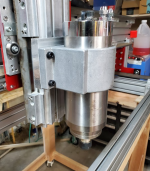

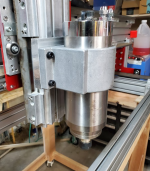

And the spindle mount adapter is finished. The more I thought about it, I thought I could probably just manually machine the adapter instead of taking a day or 2 of messing around with the ox to get it to cut aluminum.

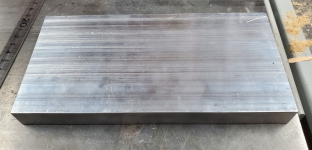

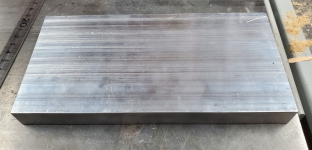

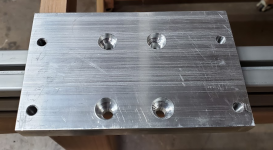

The raw material, a bar of aluminum 6"x4"x.750"

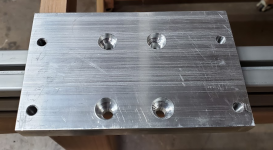

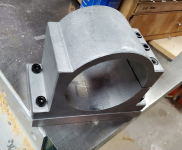

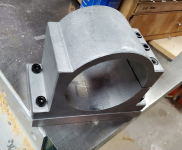

Now in order to determine where the holes are I took the spindle mount and put it on my scanner to get an image of the hole pattern. I pulled that into sketchup and used that image to make a drilling template with all the holes in the right places.

Once that matched up, I cut a little bit off the side of the bar to match the size of the mount. I redid the template to resize the holes to work with a vix bit self centering drill bit and glued the template to the aluminum bar.

I drilled some pilot holes with a 1/8" bit. For the holes that mount the spindle to the plate, I drilled the holes slightly undersize and tapped them with an M8x1.25 tap to match the bolts.

For the holes to mount the plate to the z axis, I drilled the holes so that the 8mm bolt would go through, and then took a slightly larger than 1/2" bit to countersink the hole for the cap screw. and here it is. Didn't take much more than an hour to drill and tap it all. Doing the templates and setup work took a longer, due to printing out the templates.

What do you know, a perfect fit. Even with the screws not fully tightened this does not wobble at all

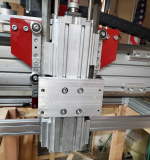

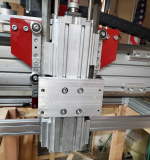

And it fits on the z axis right nice.

Couldn't be happier with how this turned out.