glenn bradley

Member

- Messages

- 11,548

- Location

- SoCal

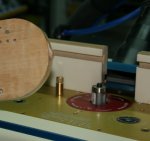

I had planned to dovetail one of my phenolic ZCI's to allow replaceable inserts but, never got around to it. Rockler had a clearance sale and the price on this commercial version was fair. I had held off putting it on until I could make some replacement inserts for it.

I am still on "light duty" so rather than wrestle a sheet of 1/4" MDF or hardboard I dug some resaw-spoil out of the scrap bin. I milled the scrap to 1/4" thickness and ripped it to width.

I used the commercial insert to set the dovetail angle.

A Marc Adams style push block works well for this long thin stock.

OK, that part fits.

I used a magnetic featherboard as a stop to cut the riving knive/blade guard slot.

Don't forget the clearance for bevel cuts.

Now that I know how to do it I should be able to make a bunch more in a batch once I'm up to it.

.

.

Like many of these things, making one doesn't really pay. Making a dozen out of scrap however, is way cheaper than paying for them.

I am still on "light duty" so rather than wrestle a sheet of 1/4" MDF or hardboard I dug some resaw-spoil out of the scrap bin. I milled the scrap to 1/4" thickness and ripped it to width.

I used the commercial insert to set the dovetail angle.

A Marc Adams style push block works well for this long thin stock.

OK, that part fits.

I used a magnetic featherboard as a stop to cut the riving knive/blade guard slot.

Don't forget the clearance for bevel cuts.

Now that I know how to do it I should be able to make a bunch more in a batch once I'm up to it.

.

.

Like many of these things, making one doesn't really pay. Making a dozen out of scrap however, is way cheaper than paying for them.

Last edited: