glenn bradley

Member

- Messages

- 11,543

- Location

- SoCal

I may be jumping the gun on this one. I realize today that it is going to take a lot longer than it should. I jacked up the tendons in my wrist doing some domestic chores a few weeks ago. Finally went to the doc . . . blah, blah, blah . . . But, why not drag you poor folks along on my slow but sure process?

This is the general idea of where I am headed although some design elements are still being discussed.

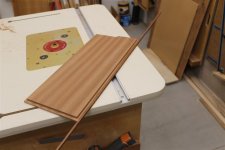

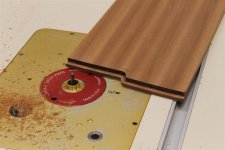

I did the design based on a large piece of sepele I had that I was going to use for the legs. Woe is me. That board is mahogany and I do not have any sepele of the proper dimensions. I am trying to use up the material I have on hand and so I decided to do glue-up legs. I cut some fat veneer.

.

.

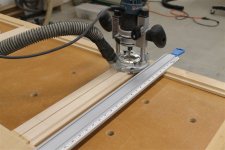

And glued up some not-quite-thick-enough sepele to meet the dimensional requirements.

.

.

This veneer will be machined down quite a bit.

.

.

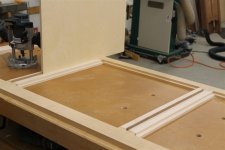

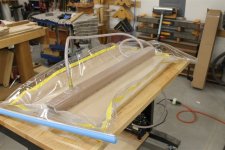

The clamping method was basically successful but for the other faces I decided to use the vacuum bag.

I milled the first two faces down a bit and applied the perpendicular faces.

.

.

cont'd . . .

This is the general idea of where I am headed although some design elements are still being discussed.

I did the design based on a large piece of sepele I had that I was going to use for the legs. Woe is me. That board is mahogany and I do not have any sepele of the proper dimensions. I am trying to use up the material I have on hand and so I decided to do glue-up legs. I cut some fat veneer.

.

.

And glued up some not-quite-thick-enough sepele to meet the dimensional requirements.

.

.

This veneer will be machined down quite a bit.

.

.

The clamping method was basically successful but for the other faces I decided to use the vacuum bag.

I milled the first two faces down a bit and applied the perpendicular faces.

.

.

cont'd . . .

Last edited:

and still regretting it as the recovery is taking longer than I wanted.

and still regretting it as the recovery is taking longer than I wanted.