Leo Voisine

Member

- Messages

- 5,730

- Location

- East Freeetown, Massachusetts

Lately, I have been organizing all my cutters for my CNC machine.

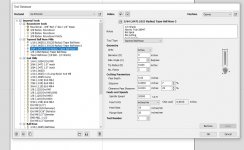

Vectric has a pretty nice database whereas you can have all your cutters set up for different materials. Softwood, hardwood, HDU, MDF, plastics, brass, steels etc etc

I have 75 different cutters for my CNC machine that I have collected over the years.

At this time I have seperated them into a draw cabinet and labeled all the little drawers.

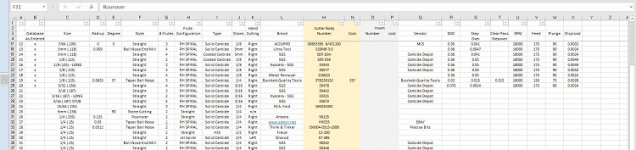

I created an Excel spreadsheet with description, source, brand, part number, style, flutes, RH or LH cutting. I am adding Speed, feed, chipload. There is more info but I don't think anyone really cares. If you do I will update.

Now - I am adding everything into the Vectric database.

This is REALLY time consuming and enormously tiring on my head. I can input about 10 entries, then I need a break.

I am backing up the database each time I make entries.

Whhooooeeeee - I need a break now.

Vectric has a pretty nice database whereas you can have all your cutters set up for different materials. Softwood, hardwood, HDU, MDF, plastics, brass, steels etc etc

I have 75 different cutters for my CNC machine that I have collected over the years.

At this time I have seperated them into a draw cabinet and labeled all the little drawers.

I created an Excel spreadsheet with description, source, brand, part number, style, flutes, RH or LH cutting. I am adding Speed, feed, chipload. There is more info but I don't think anyone really cares. If you do I will update.

Now - I am adding everything into the Vectric database.

This is REALLY time consuming and enormously tiring on my head. I can input about 10 entries, then I need a break.

I am backing up the database each time I make entries.

Whhooooeeeee - I need a break now.