So when I set up the control for the hydraulic winch, I changed out the #1 spools switch from a momentary switch to an on/off/on switch for the hydraulic motor to run in either direction constantly.

We’ll after accidentally turning that switch on getting on/off the tractor a few dozen times, I’ve decided this was a bad idea.

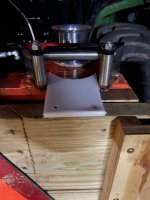

Today I put the old momentary switch back in, but I installed a 3 pin plug which also ties to 3 contacts on the switch.

View attachment 122161View attachment 122162

This allows me to plug in a remote switch to use when needed.