glenn bradley

Member

- Messages

- 11,558

- Location

- SoCal

A family friend's youngster is getting hitched. This gal and her sister hold a special place in my heart as they played a heavy part (back when they were two giggly teenage girls) in causing LOML and myself to bump into each other. Needless to say I want to make them something special. The betrothed love to cook together in the kitchen so a cutting board is already waiting in the wings.

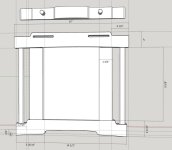

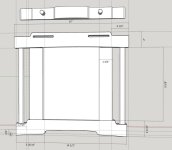

The plan is to attend the wedding, get some good pics, and then provide a picture frame a few weeks later to hold a "good one". Working with my secret delegation of spies I have landed on a design that will include a hanging strip with leather straps between the hanging strip and the frame. Something like so . . .

I am a planner and so have to make at least one prototype before I make the eventual vertical or horizontal frame (depending on what pic is the "good one") for the happy couple. I have some decently figured mahogany that will fit their decor just in case this one becomes the keeper.

This is my version of a CNC.

A little hand work . . .

Some curve fairing.

I am trying to make the templates cover the top and bottom profiles of each piece.

I'll cut the parts in the morning and report back.

The plan is to attend the wedding, get some good pics, and then provide a picture frame a few weeks later to hold a "good one". Working with my secret delegation of spies I have landed on a design that will include a hanging strip with leather straps between the hanging strip and the frame. Something like so . . .

I am a planner and so have to make at least one prototype before I make the eventual vertical or horizontal frame (depending on what pic is the "good one") for the happy couple. I have some decently figured mahogany that will fit their decor just in case this one becomes the keeper.

This is my version of a CNC.

A little hand work . . .

Some curve fairing.

I am trying to make the templates cover the top and bottom profiles of each piece.

I'll cut the parts in the morning and report back.

Last edited:

I'd be tempted to try a bit of walnut stain or dye on a test strip of the leather. Or perhaps even black.

I'd be tempted to try a bit of walnut stain or dye on a test strip of the leather. Or perhaps even black.