- Messages

- 20,168

- Location

- Springfield, Missouri

No worries, it's been great being here to learn things done first hand. I find new things he's done about every day around here too. I was up behind the pond in the holler the other day and came across this pipe/valve sticking out of the rocks.So, are you waiting to unpack the mill when the concrete pad is cleaned off so it gets assembled in place and not get tweaked during a move? If you have ever watched "Barnwood Builders" and Johnny Jett on the tele handler, you should be able to clean that pad off in less than an hour.If you have never seen it, it is worth it just to watch him manipulate the equipment and tear off a metal roof and disassemble parts.

Sorry, thought it was father in law, grandfather, better yet. A set of 4 wheeler tires on the golf cart will help it in hills on wet sod.

Chuck, I have a son in law in trucking. He used to teach at a trucking school. They now don't even teach them backing as they don't have enough time! So he went back into a truck. I enjoy the boat ramp videos, see first hand at the sale barn on Saturday mornings people trying to back to the chutes.

Anxiously awaiting updates Darren, your public is restless!

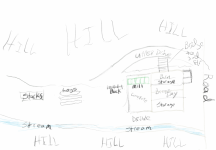

Turned out he tapped one of the springs there to pipe it down to the dairy barn for pressurized water. The crack has since shifted in the last 60 years and water just runs out the base around it.

We literally have miles of that black plastic waterline all over the property fro irrigation projects he’s done. He didn’t put in an actual well until about 1990.

I have watched barnwood builders. Johnny is quite the operator along with Sherman helping to guide.

Another great place to watch backing is at the RV parks. We like to go up a day earlier before the weekend, before most of the new arrivals come to watch the show. You certainly can tell the weekenders from the full timers.

Sorry for the delays, but been fighting the rain, helping with her uncle's place since he had to have surgery, and still need to finish up the green house siding. We'll also probably finish taking down the little house first. Got lots on my plate.

Edit: Oh, and there is yard work, lots of yard work since it is spring.

What goes in the cylindrical tank on the top?

What goes in the cylindrical tank on the top?