- Messages

- 20,168

- Location

- Springfield, Missouri

Thank you John. I did plan for some space to load saw dust on the back of the mill using the tractor.

Perhaps my use of the word slabs was incorrect, perhaps planks or boards. I may do some slabs, but will be for specific projects, mostly looking to do lumber and timbers.

There is a large door into the barn off the end of the mill, perhaps I need to rethink the placement to allow for some roll off from the rear to that door, rather than from the end of the mill. I do agree that minimal handling would be preferable.

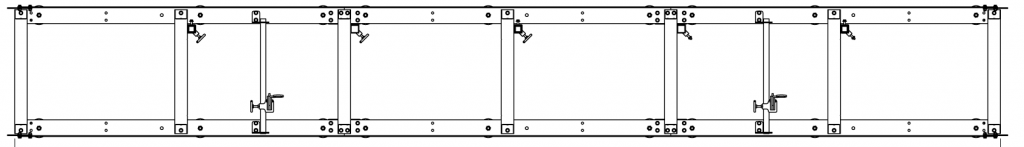

I have been thinking about a log deck to stage some logs for the mill and not use the tractor for loading each. I’ll have to consider how/where the mill would be best located to do so. My first thought would be to rotate the mill parallel to the back of the barn on the far side of the concrete and load from the side facing away from the barn, and pull boards off the back of the mill.

Perhaps my use of the word slabs was incorrect, perhaps planks or boards. I may do some slabs, but will be for specific projects, mostly looking to do lumber and timbers.

There is a large door into the barn off the end of the mill, perhaps I need to rethink the placement to allow for some roll off from the rear to that door, rather than from the end of the mill. I do agree that minimal handling would be preferable.

I have been thinking about a log deck to stage some logs for the mill and not use the tractor for loading each. I’ll have to consider how/where the mill would be best located to do so. My first thought would be to rotate the mill parallel to the back of the barn on the far side of the concrete and load from the side facing away from the barn, and pull boards off the back of the mill.