glenn bradley

Member

- Messages

- 11,551

- Location

- SoCal

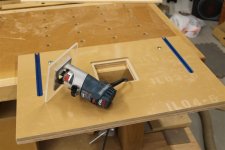

I have been telling myself to setup a temporary mini router table for some time. When I batch things like door frames, box lids, picture frames and such a second profile for the light work could save me some swap over time. We're not talking about anything production level, just a helping hand. I have the making for a second router table but have become selfish with my shop space and am unwilling to commit. A small table for the Bosh Colt seemed like the answer.

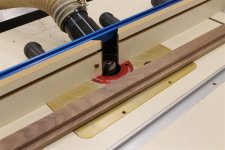

I have a spare router fence that dad used to use on his drill press but a shop made would do as well. I need four boards of equal thickness and with at least one perpendicular side and end.

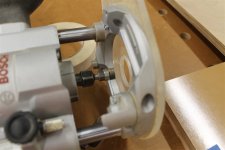

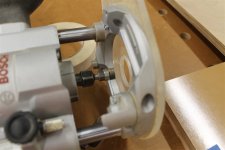

I use a hinge mortising bit. The bit diameter should match the plate's corner radius. This saves a lot of fussy fitting. I am making my own plate so I will just run the 1/2".

Stick your plate on your top in the position you want it. Then double stick tape the boards as shown and remove the plate. This method is shown in many magazines and online sources so I won't get too detailed.

I make my first pass shallow since I don't know this scrap laminated material that I was gifted. It seems to machine well.

Drill some access holes and jig saw out the center leaving a nice rabbet to hold the plate.

Not my best jig saw work but a Shinto rasp takes care of that quick and easy.

.

.

I drill bolt holes at my dog hole spacing and cut dowels. The dowels are drilled slightly off center. This will make sense later.

I meant to mention that you can see I only used the very finest quality "whatever's on hand" plywood for the substrate.

.

.

cont'd . . .

I have a spare router fence that dad used to use on his drill press but a shop made would do as well. I need four boards of equal thickness and with at least one perpendicular side and end.

I use a hinge mortising bit. The bit diameter should match the plate's corner radius. This saves a lot of fussy fitting. I am making my own plate so I will just run the 1/2".

Stick your plate on your top in the position you want it. Then double stick tape the boards as shown and remove the plate. This method is shown in many magazines and online sources so I won't get too detailed.

I make my first pass shallow since I don't know this scrap laminated material that I was gifted. It seems to machine well.

Drill some access holes and jig saw out the center leaving a nice rabbet to hold the plate.

Not my best jig saw work but a Shinto rasp takes care of that quick and easy.

.

.

I drill bolt holes at my dog hole spacing and cut dowels. The dowels are drilled slightly off center. This will make sense later.

I meant to mention that you can see I only used the very finest quality "whatever's on hand" plywood for the substrate.

.

.

cont'd . . .

Last edited: