- Messages

- 11,632

- Location

- Constantine, MI

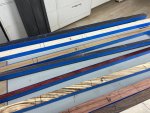

This is going to be a clock. Not my design - based on a customer's wishes. I let him have full responsibility for the design which has proven to be an experience in itself. He's a little OCD and this was a challenge for him! We exchanged no less than 28 pictures of the layout over the last week. He would mark up each picture, first swapping sticks to get the mix right, and then tweaking the position back and forth to get the edge spacing correct.

We're all done tweaking so I've marked up the back to keep everything in order and now each piece has to be sanded, the dye on the maple will have to be touched up and the same for the ebonizing of the walnut. I'll glue up about 5 at a time by laying down a light bead of glue, flushing up the backs, and popping a few brads to hold them in line when clamped. The finish will be rattle can lacquer. There will be 1/4 x 1/2 aluminum bar routed into the face at 12/6 and 3/9. All the bars will be the same length because... The hanging will be interesting. I'll attach four french cleats to the back so it can be hung in four different orientations - hence the bar length.

Seems he likes his idea so much that I am also making a smaller version now for his kitchen. The large one is roughly 26" square and the smaller one will be roughly 12" square.

We're all done tweaking so I've marked up the back to keep everything in order and now each piece has to be sanded, the dye on the maple will have to be touched up and the same for the ebonizing of the walnut. I'll glue up about 5 at a time by laying down a light bead of glue, flushing up the backs, and popping a few brads to hold them in line when clamped. The finish will be rattle can lacquer. There will be 1/4 x 1/2 aluminum bar routed into the face at 12/6 and 3/9. All the bars will be the same length because... The hanging will be interesting. I'll attach four french cleats to the back so it can be hung in four different orientations - hence the bar length.

Seems he likes his idea so much that I am also making a smaller version now for his kitchen. The large one is roughly 26" square and the smaller one will be roughly 12" square.