Sean Wright

Member

- Messages

- 902

- Location

- WNY, Buffalo Area

Without a doubt I am a power tool guy, but I do appreciate & respect the skill involved in working wood with traditional hand tools. So once a week I record an episode of "The Woodwright's Shop" with Roy Underhill. I like to see different and more traditional ways of how things were done. I suppose knowing about where the craft came from and evolved helps me in its "modern-power tool based" practice.

Anyways..... Last week Roy did an entire episode on differnet types of dovetails. He showed a mortice and tennon dovetail joint. This is something that was entirely new to me.

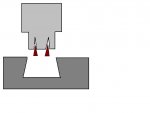

He made a tennon with 2 kerf cuts in the end of the tennon. He then cut a mortice that was in the shape of a dovetail (narrow at the opening(top), and wider at the bottom). He then tapped a wedge into each kerf in the tennon, but not far enough to make the tennon spread wider. He then tapped the piece of wood with the wedges sticking out of the tennon into the mortice. When the tennon bottomed out in the mortice, the wedges spread the kerfs wide enough that the tennon was then locked into the mortice by the dovetail shape and friction.

I have seen a version of this where the mortice was a through-mortice where the wedges spread the tennon pinning it in place, but not one done this way.

I did a quick sketch of what this looked like, incase my description was confusing.

Has anyone else seen or used this type of joint before?

Anyways..... Last week Roy did an entire episode on differnet types of dovetails. He showed a mortice and tennon dovetail joint. This is something that was entirely new to me.

He made a tennon with 2 kerf cuts in the end of the tennon. He then cut a mortice that was in the shape of a dovetail (narrow at the opening(top), and wider at the bottom). He then tapped a wedge into each kerf in the tennon, but not far enough to make the tennon spread wider. He then tapped the piece of wood with the wedges sticking out of the tennon into the mortice. When the tennon bottomed out in the mortice, the wedges spread the kerfs wide enough that the tennon was then locked into the mortice by the dovetail shape and friction.

I have seen a version of this where the mortice was a through-mortice where the wedges spread the tennon pinning it in place, but not one done this way.

I did a quick sketch of what this looked like, incase my description was confusing.

Has anyone else seen or used this type of joint before?