david graves

Member

- Messages

- 69

- Location

- Mississippi

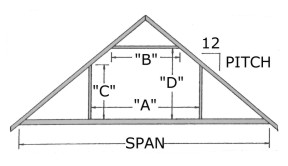

My garage (converted to my shop) also has access to a large the attic space via pull down stairs, but unfortunately the truss system takes up all the space. Suggest you get a truss system designed to allow for storage. Something like this:

The truss designers will design it to handle loads. It should not cost much more than a normal roof truss. Much better way to go.

The disappearing stairs are for access to the two air conditioning units and water heater. I will use some are for light storage but not much.

The roof pitch is only going to be 7/12. My residence is all 10/12 and 12/12 and I can't get my fat butt up there. I want a roof that I can walk on and 7/12 is about the max for me.

Regards,