Ned Bulken

Member

- Messages

- 5,529

- Location

- Lakeport NY and/or the nearest hotel

OK youse guys. I'm headed to VA next weekened and will be visiting my parents for the hollydaze. My dad has taken possession of the Mark V and it is supposedly in fine shape. I was thinking of taking a few gouges and my sharpening station with me and making a mess of his shop for a few hours over the course of the visit.

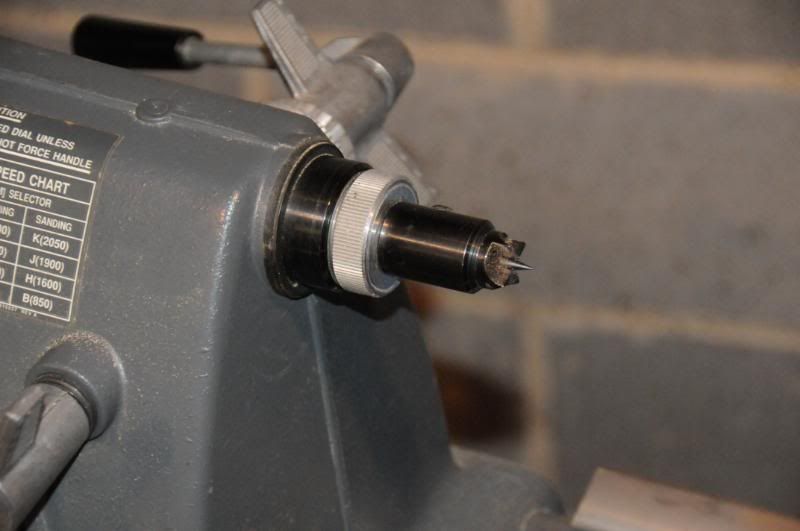

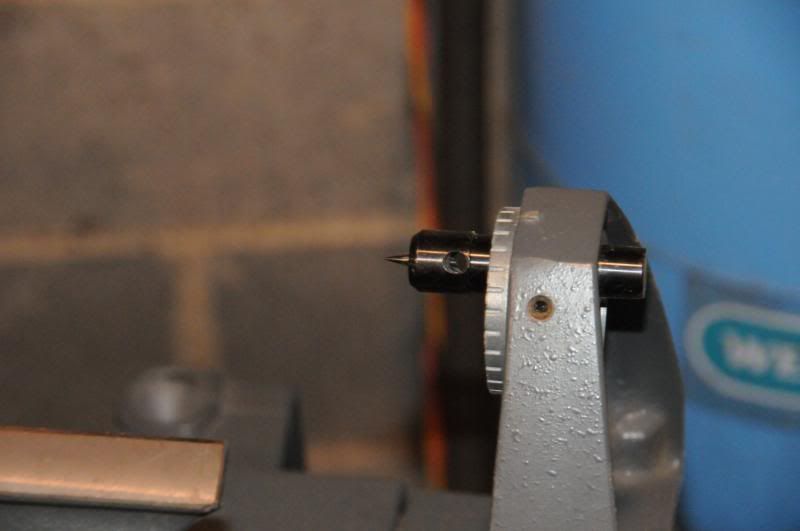

Presuming that my uncle who originally owned the Mark V had 'nearly everything', what can I expect to find when I get down there? Will it have a chuck or will I be turning between centers? Does it Come with Centers?

If it doesn't, I guess I'll be loading up my Midi and taking that with me for entertainment (his basement shop is heated and mine is still drafty and unused now that winter has arrived)

Presuming that my uncle who originally owned the Mark V had 'nearly everything', what can I expect to find when I get down there? Will it have a chuck or will I be turning between centers? Does it Come with Centers?

If it doesn't, I guess I'll be loading up my Midi and taking that with me for entertainment (his basement shop is heated and mine is still drafty and unused now that winter has arrived)

Last edited: