Stuart Ablett

Member

- Messages

- 15,917

- Location

- Tokyo Japan

As I mentioned in >> THIS << thread about restoring my old MT bike, I want to build a bicycle trailer for doing my daily deliveries around the area.

I've done a bit or research on this, here is part of what I found.....

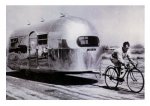

This is a trailer that is being built and sold here in Japan.

>> Trailer on the move <<

>> How It Hitches <<

And I found this website, they sell the trailers ready to go for about $300.....

>> Bicycle Trailer <<

Overall, there is nothing wrong with that trailer, the size is not what I want, I have very specific dimensions I need to fit my cases of beer etc.

I do like his hitch and we contacted him about just buying that part, but he would not sell it, so I found the gimble or pivot part for sale for about $10, so I guess I'll just fabricate the rest.

Here in Tokyo, we have seen a lot of the courier guys now using electric bikes with trailers to do parcel deliveries.......

I also found a lot of information online >> HERE << about stability and hitch location.

I think I will have the hitch on the seat post, and I'll build the trailer bed fairly low to the ground, maybe 4" or so off the deck, well below the axle of the wheels. I've also decided to use regular 26" wheels, I'm told that they will give me much less rolling resistance, and I can get them with tire and tubes for free, when my local neighbourhood bicycle shop takes an old bike when a customer is buying a new bike.

I'm trying to make a SU drawing, but I'm having troubles, I'm not very good at SU

I've done a bit or research on this, here is part of what I found.....

This is a trailer that is being built and sold here in Japan.

>> Trailer on the move <<

>> How It Hitches <<

And I found this website, they sell the trailers ready to go for about $300.....

>> Bicycle Trailer <<

Overall, there is nothing wrong with that trailer, the size is not what I want, I have very specific dimensions I need to fit my cases of beer etc.

I do like his hitch and we contacted him about just buying that part, but he would not sell it, so I found the gimble or pivot part for sale for about $10, so I guess I'll just fabricate the rest.

Here in Tokyo, we have seen a lot of the courier guys now using electric bikes with trailers to do parcel deliveries.......

I also found a lot of information online >> HERE << about stability and hitch location.

I think I will have the hitch on the seat post, and I'll build the trailer bed fairly low to the ground, maybe 4" or so off the deck, well below the axle of the wheels. I've also decided to use regular 26" wheels, I'm told that they will give me much less rolling resistance, and I can get them with tire and tubes for free, when my local neighbourhood bicycle shop takes an old bike when a customer is buying a new bike.

I'm trying to make a SU drawing, but I'm having troubles, I'm not very good at SU