- Messages

- 8,633

- Location

- Thomasville, GA

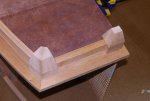

Today was primarily alignment and anchoring of the internal panels and massaging other parts to final fit. I ran some thin resawn mahogany thorugh my drum sander to get it to 1/32" to use for edge-banding the front edge of the panels. The photo shows the banding 'clamped' in place with blue tape. The other clamps on top are simply holding the panels in place; MDF spacers are between the panels.

I ran a radius on a piece of MDF to use as a fence for the curved top and bottom rails of the doors. I plan to run the dado in the rails tomorrow.

With all the stuff I've scattered about, it was time to do a bit of cleanup at the end of the day.

See y'all tomorrow!

I ran a radius on a piece of MDF to use as a fence for the curved top and bottom rails of the doors. I plan to run the dado in the rails tomorrow.

With all the stuff I've scattered about, it was time to do a bit of cleanup at the end of the day.

See y'all tomorrow!