larry merlau

Member

- Messages

- 18,741

- Location

- Delton, Michigan

so are the face frames and the doors gonna be painted as well chuck? if not then how are you gonna secure them to the boxes?

)

)Can do that Bob but you'll have to talk to KaLea the kitchen designer first.Since I know nothing about building cabinets and my wife is bugging me for new ones I would sure like a picture or two to help me along. (or maybe an estimate for you to build us new cabinets)

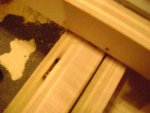

well i would say you beaded that just fine chuck

and lost a couple to tear out on the jointer

and lost a couple to tear out on the jointer  but was able to save them for other spots unlike the beaded ones that could not be ripped down for another use.

but was able to save them for other spots unlike the beaded ones that could not be ripped down for another use.