- Messages

- 20,138

- Location

- Springfield, Missouri

Well, it's been a day of trying to do that. In the past month my bench grinder and my 1" x 30" belt sander both quit working.

The belt sander is from HF and I've had it about 5 years now. It was working pretty well and had been running for a good 30 minutes, then after shutting off it would only hum when trying to turn on again...typically the tail tail sign of a bad capacitor

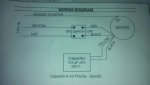

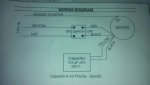

Today I looked up the wiring diagram on the HF site and found indeed it had a capacitor.

Based on the size of the motor and the fact it had a larger than needed box for the switch, I assumed the capacitor was in the box as well.

Using my digital ohm meter I set it to the 1k setting. I touch one probe on each wire for a few seconds, then reversed the probes/wires. I didn't get a reading. Typically you should see at least some reading when you reverse the probes. So between the hum of the motor and no reading change on the capacitor, it's probably bad.

A quick google, I wasn't able to find an exact match without shipping it from hong kong, but grainger had a similar one in stock for $6 that I'll be picking up this week. Just thought I'd document this little fix as I'm sure some of you have ran into this same issue before. One tip, the voltage rating on the new capacitor just needs to be as much or higher than what your tool runs, but the microfarad rating needs to be within tolerance. So though I took a 250 volt cap out, I'm replacing it with a 125 volt cap with the same microfarad rating.

So, on to the grinder. The I had just finished sharpening the blades on my riding motor, shut it off and decided to sharpen the push mower blade as well. As I turned on the grinder, sparks and smoke shot out both sides of the vent holes. Well, it looks like some of the insulation overheated and shorted the windings, the yellow insulation look to be chewed up by a mouse, but they are actually melted through.

Needless to say, this grinder is about 30 years old, I remember my dad buying it. The bearings are starting to rattle and it's needing new wheels anyway, so I'll be picking up a new grinder soon. Any recommendations for a new one?

The belt sander is from HF and I've had it about 5 years now. It was working pretty well and had been running for a good 30 minutes, then after shutting off it would only hum when trying to turn on again...typically the tail tail sign of a bad capacitor

Today I looked up the wiring diagram on the HF site and found indeed it had a capacitor.

Based on the size of the motor and the fact it had a larger than needed box for the switch, I assumed the capacitor was in the box as well.

Using my digital ohm meter I set it to the 1k setting. I touch one probe on each wire for a few seconds, then reversed the probes/wires. I didn't get a reading. Typically you should see at least some reading when you reverse the probes. So between the hum of the motor and no reading change on the capacitor, it's probably bad.

A quick google, I wasn't able to find an exact match without shipping it from hong kong, but grainger had a similar one in stock for $6 that I'll be picking up this week. Just thought I'd document this little fix as I'm sure some of you have ran into this same issue before. One tip, the voltage rating on the new capacitor just needs to be as much or higher than what your tool runs, but the microfarad rating needs to be within tolerance. So though I took a 250 volt cap out, I'm replacing it with a 125 volt cap with the same microfarad rating.

So, on to the grinder. The I had just finished sharpening the blades on my riding motor, shut it off and decided to sharpen the push mower blade as well. As I turned on the grinder, sparks and smoke shot out both sides of the vent holes. Well, it looks like some of the insulation overheated and shorted the windings, the yellow insulation look to be chewed up by a mouse, but they are actually melted through.

Needless to say, this grinder is about 30 years old, I remember my dad buying it. The bearings are starting to rattle and it's needing new wheels anyway, so I'll be picking up a new grinder soon. Any recommendations for a new one?