Hi Larry,

A huge factor in efficiency is how you run your ducts.

Really, really, really try not to have any 90* turns. Do a 45* ell into a short coupling (translate that to 6inch length of your 6 inch ducting) into another 45* ell. It takes 3 inches of pipe to go into a fitting, so the two 45* ells use up 6 inches of pipe so they can fit coupling to coupling. You can make the coupling longer if you wish.

Do not use any more flex than is absolutely necessary.

Be sure that all blast gates, except the one you are using right now, are closed.

My set up is a 2hp PennState. With this setup I am satisfactory. I do not have ANY surplus. If a second blast gate is open, my efficiency drops like a rock. My setup is inadequate to use a "Big Gulp" type of thing at the lathe. I have to use two of the flex-duct pipes that stay in the position where I put them. That means I have to adjust them every time I work on a different section of the turning.

My bandsaws, drill press, thickness planer, sanders, table saw and router (router has its own ShopVac) all work fine.

I cannot remember the impeller size. I do remember that the amperage is low for a real 2hp motor. They claim 1,500 CFM. Don't get me wrong. I am not buying a new DC. This one works well enough to keep me happy---and I really, really, to not like wood dust. However, If I had been more knowledgeable at the time of purchase I would have purchased a gutsier unit.

I purchased the PennState (DC2000) because it had one micron bags. To me that is extremely important. It is the fine stuff you cannot see that kills you. The one micron bags ended up not really mattering because I built a shed outside of my shop to house the DC (and give me more storage).

The other factor was the price. Read the data on other DCs and compare to the PennState. With 1 micron bags 1,500 CFM etc. you will find that they have a higher price.

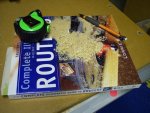

The "dust" on the cover of the magazine is all of the dust removed from an 18-foot section of 6 inch pipe after several years of use---everything else made it to the dust collector bag. The pic showing the three pipes joining and going through the wall is where the system leaves the shop and goes next door into the dust collector itself.

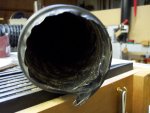

One pic shows two 45* ells making a 90* turn. Another pic shows the end of a piece of 4 inch flex that was a drop from the 6-inch to a machine. It had been used for several years.

If you have any questions, ASK.

Enjoy,

JimB