glenn bradley

Member

- Messages

- 11,559

- Location

- SoCal

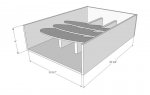

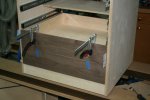

Thanks for the kind words all . . . With a carcass this wide and no face-frame for support, I add a sort of 'stretcher-panel'. This attaches to the sides with pocket holes and runs about 2/3 of the depth of the cabinet. The drawer box heights and spacing are designed with this in mind. The false fronts will disguise this deviation in spacing.

Tomorrow I can start on the false-fronts and pulls. Once I have the drawer positions fine tuned, I'll attach the back and give the outer shell a topcoat. The inside faces of the drawer parts and the drawer bottoms were finished with shellac prior to assembly.

.

.  .

.  .

.

The height was determined by the clearance required for my fence DRO. The width was determined by the room I had available once I had assured that I could easily reach all of the saw controls without banging into things. The depth is enough less than the depth of the saw to allow me to set the cabinet back a few inches so I can stand and work in that area without kicking the cabinet.

Tomorrow I can start on the false-fronts and pulls. Once I have the drawer positions fine tuned, I'll attach the back and give the outer shell a topcoat. The inside faces of the drawer parts and the drawer bottoms were finished with shellac prior to assembly.

.

.  .

.  .

.

The height was determined by the clearance required for my fence DRO. The width was determined by the room I had available once I had assured that I could easily reach all of the saw controls without banging into things. The depth is enough less than the depth of the saw to allow me to set the cabinet back a few inches so I can stand and work in that area without kicking the cabinet.

Last edited: