Sean Wright

Member

- Messages

- 902

- Location

- WNY, Buffalo Area

I am starting to research Dust Collection, as it needs to be my next addition to the shop. I know that ideally a cyclone is the best way to go. Unfortuntaly that is just way out of my price range.(even on the low end $800 and up  ) I was reading on Stu's site about how he made his. I am very impressed

) I was reading on Stu's site about how he made his. I am very impressed  Unfortunatly I don't have a welder or welding abilities to fabricate one. I also don't have a lot of over head room. The bottom of the floor joists (effectively the ceiling of my shop) are about at 7 feet.

Unfortunatly I don't have a welder or welding abilities to fabricate one. I also don't have a lot of over head room. The bottom of the floor joists (effectively the ceiling of my shop) are about at 7 feet.

I was looking at the Delta 50-760 and the Steel City 65200, because of the 1 micron filters.

I have the following tools that would be connected to the DC system: table saw, joiner, planer, band saw, compound miter saw, sanding station, random orbit sander, belt sander(as soon as I get the DC addaptor), router table / connection for plunge router.

In place of a true cyclone, has anyone had an sucess in using a seperator (mounts on a garbage can, inline before the DC)? Is this worth having to catch the big stuff before it hits the DC?

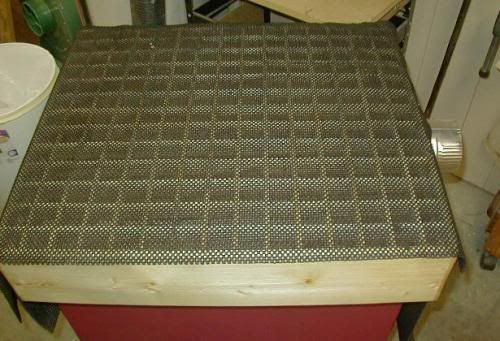

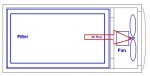

Also is it possible to build a down draft table, using the suction from a DC... or would it need its own vaccum/blower?

Any and all suggestions / recommendations are welcome !

Delta 50-760 Specs:

Motor 1.5 HP

Maximum CFM 1200

Motor Specs 3450 RPM, 120/240V, single phase, 60 Hz

Impeller Diameter 11.5"

Filter Bag Area (Total) 20.5 square feet, 1.9 square meters

Standard Bag Filtration 1 Micron Chip Bag Area (Total) 2.4 cubic feet, 67 liters

Overall Dimensions Length: 35", Width: 19", Height: 83"

Max. Static Pressure (in water) 8

Decibel Rating 88 dB

Steel City 65200 Specs:

Motor: 1.5 HP, 115V/230V, 60 Hz TEFC

Motor Control: Industrial Push Button

Max. CFM: 1,200 CFM

Static Pressure: 11.1 (inches of water)

Bag Filtration: 1 micron

Chip Capacity: 6.3 Cu. Ft.

Impeller: Steel

Blow Wheel Diameter: 11 1/2"

Number of Intakes: 2 - 4

Hose Diameter: 4"

Decibel Reading: 87 dB

Unfortunatly I don't have a welder or welding abilities to fabricate one. I also don't have a lot of over head room. The bottom of the floor joists (effectively the ceiling of my shop) are about at 7 feet.

Unfortunatly I don't have a welder or welding abilities to fabricate one. I also don't have a lot of over head room. The bottom of the floor joists (effectively the ceiling of my shop) are about at 7 feet. I was looking at the Delta 50-760 and the Steel City 65200, because of the 1 micron filters.

I have the following tools that would be connected to the DC system: table saw, joiner, planer, band saw, compound miter saw, sanding station, random orbit sander, belt sander(as soon as I get the DC addaptor), router table / connection for plunge router.

In place of a true cyclone, has anyone had an sucess in using a seperator (mounts on a garbage can, inline before the DC)? Is this worth having to catch the big stuff before it hits the DC?

Also is it possible to build a down draft table, using the suction from a DC... or would it need its own vaccum/blower?

Any and all suggestions / recommendations are welcome !

Delta 50-760 Specs:

Motor 1.5 HP

Maximum CFM 1200

Motor Specs 3450 RPM, 120/240V, single phase, 60 Hz

Impeller Diameter 11.5"

Filter Bag Area (Total) 20.5 square feet, 1.9 square meters

Standard Bag Filtration 1 Micron Chip Bag Area (Total) 2.4 cubic feet, 67 liters

Overall Dimensions Length: 35", Width: 19", Height: 83"

Max. Static Pressure (in water) 8

Decibel Rating 88 dB

Steel City 65200 Specs:

Motor: 1.5 HP, 115V/230V, 60 Hz TEFC

Motor Control: Industrial Push Button

Max. CFM: 1,200 CFM

Static Pressure: 11.1 (inches of water)

Bag Filtration: 1 micron

Chip Capacity: 6.3 Cu. Ft.

Impeller: Steel

Blow Wheel Diameter: 11 1/2"

Number of Intakes: 2 - 4

Hose Diameter: 4"

Decibel Reading: 87 dB

Last edited: