Thank you Glenn, and everyone else.

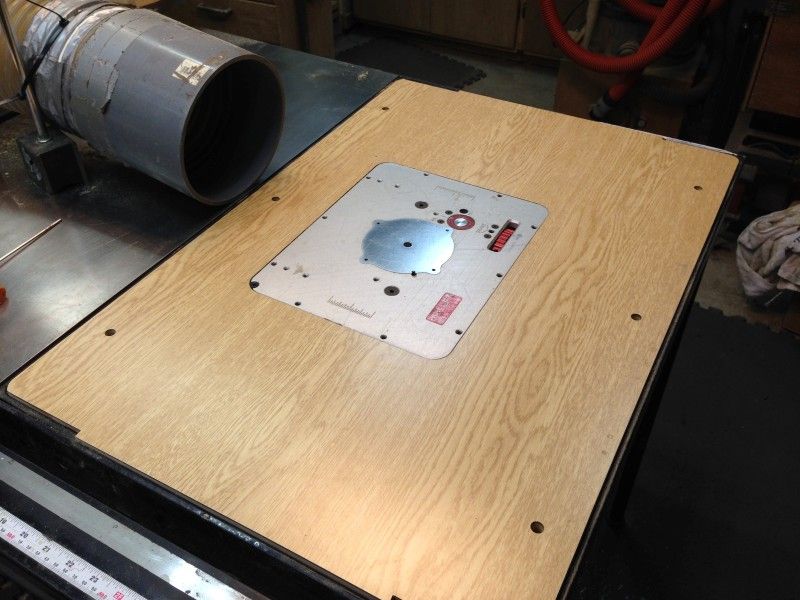

OK, now I need to make a DC connection for this table, as most of you know, the router even in a table, is a VERY messy tool, it spits sawdust here there and everywhere! The only tool that is messier, in my mind, is the lathe when I'm roughing green blanks, but those chunks are much larger, the router makes VERY fine dust that is NOT good to be floating around in a confined space.

I want to get this done and move on to making the doors for my

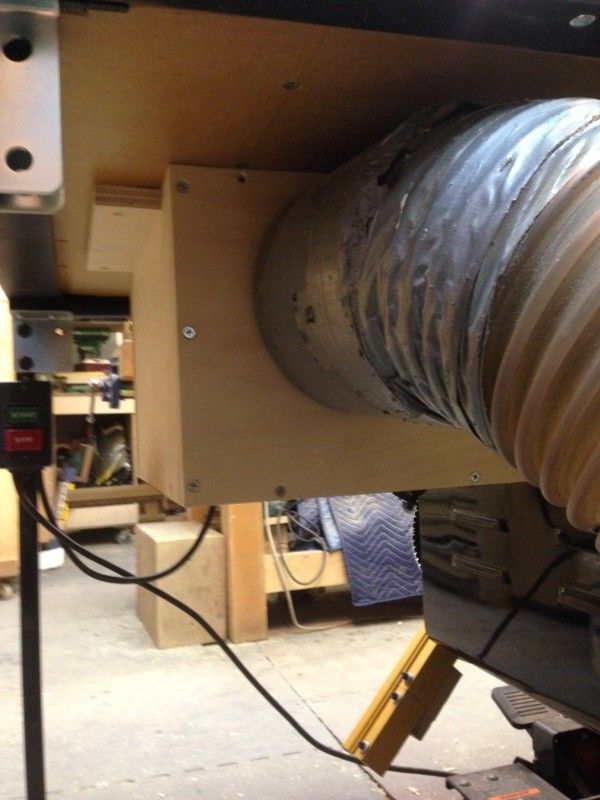

Cigar Humidor build, to get that done, but I also know that if I just build a cowl around the bottom of the new router table to collect the dust, and don't build a the cabinet that I want to live under that wing of the tablesaw, it could be years before I get around to building said cabinet, not the best outcome.

Right now as I sit in my Dungeon I am planing the cabinet/DC cowl my main head scratcher is how the air should flow around the router. When I routed out the top of the table I just built, I took the Milwaukee 5625 router motor apart that I use in the table, and it was packed full of sawdust, not good.

I cannot find it now, but I remember seeing a post on a thread somewhere, by someone (sorry I forgot who) that shows a DC surround that has a top side DC inlet and a fresh air inlet on the bottom of the surround. The idea is that the dust gets drawn off the side/top nearest to the cutter, and the clean air that goes into the cabinet comes from the bottom, this allows clean air to flow over the motor and up into the top/side inlet. I like this idea, it makes sense to me, but I have to work on how to make it work, and build a cabinet around it.

Wish me luck!

I would say it looks like it was molded in.