Still playing around with this. Well, as it usually goes with these things, I'm still having issues getting the little wifi module to work properly. I think I need to re-flash the firmware, and have seen on the web where someone soldered up a jig to make it a little easier to do than running a bunch of jumper wires on the breadboard.

I figured this would be a perfect opportunity to learn how to use a program to both document the circuitry for the jig, as well as design the pcb.

So I'm using

'fritzing', an open source tool for designing electronics.

It's very breadboard friendly. You can design your tool in a breadboard mode and work in schematic and PCB modes. It will also generate all of the files required for creating PCB's.

So, I'm going to burn this one and give it a shot.

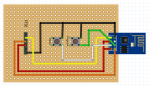

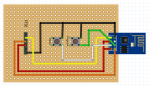

Breadboard Mode

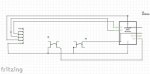

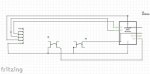

Schematic Mode

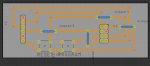

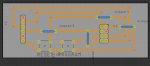

PCB Layout mode.

You can see here that since I've got it as a single sided copper PCB, I had to add in some 'jumpers' in order to get this to route the traces. Alternatively, I could have done a double sided board and would not have had to have done the jumpers. Not sure I'm up to the task of double sided boards yet.

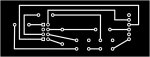

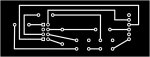

so I exported that design to an SVG file, made the traces a little bigger, exported to a png file, inverted the colors and created a bitmap that I used to create the G-code file.

Now to see how this all works!