- Messages

- 20,145

- Location

- Springfield, Missouri

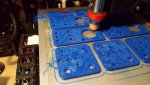

Sometimes the quality of the filament isn't the filament itself. I had a job running to create some openbuild plates that failed twice on me due to the way the filament was wrapped on the reel.

I came out in the morning to find the reel almost falling off the shelf each time about 2 hours into a 9 hour job. I untangled it and about 2 meters later it was tangled again, so this reel wont be used again, it was the Argos brand.

The filament itself was working fine, maybe if I empty another reel I may try re-winding it onto a new reel, but cost wise it really isn't worth it.

I also need to print a new nozzle cooler as this one fell off and got melted when the reel hung up.

I came out in the morning to find the reel almost falling off the shelf each time about 2 hours into a 9 hour job. I untangled it and about 2 meters later it was tangled again, so this reel wont be used again, it was the Argos brand.

The filament itself was working fine, maybe if I empty another reel I may try re-winding it onto a new reel, but cost wise it really isn't worth it.

I also need to print a new nozzle cooler as this one fell off and got melted when the reel hung up.