- Messages

- 21,144

- Location

- Springfield, Missouri

Not as cool as the one Jay has, but I had bought a 2w laser from http://jtechphotonics.com about a year and a half ago. I had planned to use it on my cnc, but found that Mach3, my controller software, added a bunch of pauses during Z axis movements. This basically caused any pictures to come out as burnt toast. The laser isn't strong enough to really cut much, but will let me do some engraving, which I what I'm wanting to do.

Given I now have the 3d printer, I figured I'd give building a new x-y table for it a try.

There were several designs on thingiverse and openbuilds.com, but the one I settled on was one using openbuilds parts (http://www.thingiverse.com/thing:1233664). I've scaled it up a little to about 15" wide and may go up to about 36" wide, but haven't decided yet. I'd like to see the materials and decide what will work for my needs.

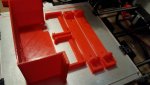

Over the last week I've been trying to print the parts for it, but between bad filament and temperature issues (warping), I've had a hard time getting them printed.

The last couple of days I've gotten things worked out and I've just about got them done, still have some legs to print out.

I'm planning to use a Grbl Controller, which is what the Xcarve and Shapeoko tables use as their controller, and you can get them for $12.99

I'm still waiting on the last of the parts to come in, but have enough to get the motors and controller running and tested out.

For the Sender, I'm trying to decide on using LaserWeb (http://www.openbuilds.com/projectresources/laserweb-laser-controller-software.191/) or Mr. Beam (https://wiki.mr-beam.org/doku.php?id=software_releases), which uses a Raspberry pi also connected to the arduino controlling the laser.

Any, more to come later.

Last edited: