Carol Reed

In Memoriam

- Messages

- 5,533

- Location

- Coolidge, AZ

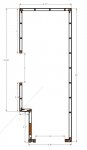

I know tiny houses are a big fad now but I have the house. Now to build a shop. I am allowed 120 square feet. Period. The shape is also limited and given all the perimeters and restrictions, I have that worked out to 119.8 square feet. Here is the shape.

The side entry leads to a 3' required breezeway between the shop and house. Expect tp use that space for SCMS which is on a portable base.

The jog in the left wall accommodates a require 3' easement to get around the stairs into the house.

Th opening at the bottom allows infeed to the table saw, extra room around the floor standing drill press, and ingress/egress to power tools on wheels. This whole structure sits under the carport, so plenty of assembly area outside of the shop and under cover. The band saw will sit next to the side opening to the left as you go in. The drill press will sit next to the bottom opening just to the left. Everything else is on wheels.

The exterior walks will go to the top of the carport allowing a storage deck over the side opening along that entire wall and another over the bottom door.

I think I have met all the requirements of the park.. Will go for approval this week. If that is a go, then the build is pretty straight forward and then the fun begins.

So your job, if you are up to it, is make suggestion about clever storage and primary tools to include. Here is the list to choose from, in no particular order: Radial arm saw, bench top planer, Performax sander (24"), floor standing spindle sander, welding cart, metal cutting band saw, floor standing oscillating edge sander, mortiser, air compressor, assorted shop vacs, vacuum pump cart, buddy cart, fold up tables, saw horses, 2 rolling tool boxes, 5 4 drawer file cabinets, and jointer. Obvisouly, it will not all fit and there is a 4'x2' CNC coming.

I also have a side room on the house that can be used for shop purposes, so that is area 2. Here is the task at hand. Which tools should be in the shop, which is area 2, and which are going to be on the sales block. (The lathe is already for sale). I expect tp use the shop for making myself furniture for the house.

I need to resolve this issue because the next planning is for electrical which will/required to done by a licensed electrician. The table saw and the CNC require 220V. Everything else is 120V.

This is what is on hand. Doesn't mean some things can't go or be further downsized. So let's have your thoughts, if this were your problem to solve.

The side entry leads to a 3' required breezeway between the shop and house. Expect tp use that space for SCMS which is on a portable base.

The jog in the left wall accommodates a require 3' easement to get around the stairs into the house.

Th opening at the bottom allows infeed to the table saw, extra room around the floor standing drill press, and ingress/egress to power tools on wheels. This whole structure sits under the carport, so plenty of assembly area outside of the shop and under cover. The band saw will sit next to the side opening to the left as you go in. The drill press will sit next to the bottom opening just to the left. Everything else is on wheels.

The exterior walks will go to the top of the carport allowing a storage deck over the side opening along that entire wall and another over the bottom door.

I think I have met all the requirements of the park.. Will go for approval this week. If that is a go, then the build is pretty straight forward and then the fun begins.

So your job, if you are up to it, is make suggestion about clever storage and primary tools to include. Here is the list to choose from, in no particular order: Radial arm saw, bench top planer, Performax sander (24"), floor standing spindle sander, welding cart, metal cutting band saw, floor standing oscillating edge sander, mortiser, air compressor, assorted shop vacs, vacuum pump cart, buddy cart, fold up tables, saw horses, 2 rolling tool boxes, 5 4 drawer file cabinets, and jointer. Obvisouly, it will not all fit and there is a 4'x2' CNC coming.

I also have a side room on the house that can be used for shop purposes, so that is area 2. Here is the task at hand. Which tools should be in the shop, which is area 2, and which are going to be on the sales block. (The lathe is already for sale). I expect tp use the shop for making myself furniture for the house.

I need to resolve this issue because the next planning is for electrical which will/required to done by a licensed electrician. The table saw and the CNC require 220V. Everything else is 120V.

This is what is on hand. Doesn't mean some things can't go or be further downsized. So let's have your thoughts, if this were your problem to solve.