glenn bradley

Member

- Messages

- 11,558

- Location

- SoCal

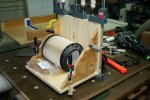

This is an additional but, redesigned version of this prototype from some years back. I should probably mention that I get a kick out of building this sort of thing out old, cast off IKEA furniture.

Another small to-do I have been meaning to get to since . . . . well, its been a couple of YEARS since I bought this Ridgid vac at a Home Depot Black Friday sale!?!

I have one of these that I call version 1. It was made on-the-fly out of some real crummy particle board as a proto-type. It has worked fine and so still survives. I will move version 1 over to the drill press / small bandsaw area and version 2 will become the main shop vac / hand held power tool vacuum system.

Both version 1 and version 2 will use Ridgid’s vac that converts to a yard vac/blower. This just makes the conversion easier. The idea is to eliminate the massive barrel as when using the Dust Deputy, the barrel remains pretty much empty.

I learned on version 1 that reinforcing the bucket lid is a good idea. Clogs or unexpected blocking of the vac nozzle can cause a reasonable amount of suction at the bucket and the stock Oneida bucket/top flexes a lot where the cone meets the bucket lid.

The overall design places the filter in a small chamber that can be cleaned out if required. I clean mine about twice a year and get a couple of teaspoons of stuff in the filter chamber. Nearly all the spoil gets separated into the bucket under the DD.

I cut a hole to fit the neck of the filter. I then use a roundover bit at the router table to make the fit a bit more custom.

.

.

.

.

conti'd

Another small to-do I have been meaning to get to since . . . . well, its been a couple of YEARS since I bought this Ridgid vac at a Home Depot Black Friday sale!?!

I have one of these that I call version 1. It was made on-the-fly out of some real crummy particle board as a proto-type. It has worked fine and so still survives. I will move version 1 over to the drill press / small bandsaw area and version 2 will become the main shop vac / hand held power tool vacuum system.

Both version 1 and version 2 will use Ridgid’s vac that converts to a yard vac/blower. This just makes the conversion easier. The idea is to eliminate the massive barrel as when using the Dust Deputy, the barrel remains pretty much empty.

I learned on version 1 that reinforcing the bucket lid is a good idea. Clogs or unexpected blocking of the vac nozzle can cause a reasonable amount of suction at the bucket and the stock Oneida bucket/top flexes a lot where the cone meets the bucket lid.

The overall design places the filter in a small chamber that can be cleaned out if required. I clean mine about twice a year and get a couple of teaspoons of stuff in the filter chamber. Nearly all the spoil gets separated into the bucket under the DD.

I cut a hole to fit the neck of the filter. I then use a roundover bit at the router table to make the fit a bit more custom.

.

.

.

.

conti'd

Last edited: