Greg Karnow

Member

- Messages

- 2

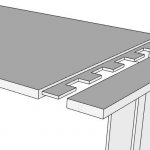

What are the guidelines for determining the depth and width of a mortise and tenon for a breadboard end on a table? Or is it arbitrary?

Thanks!

Sent from my SM-G928V using Tapatalk

Thanks!

Sent from my SM-G928V using Tapatalk