- Messages

- 20,175

- Location

- Springfield, Missouri

Thanks! Yeah, I ordered one of those lighting kits t try out, but do plan to make my own also.

| Basic Costs | Cost | Notes |

| K40 - Analog Version | $334.59 | ebay: https://www.ebay.com/itm/172688600658 use k40Whisperer and inkscape plugin (both free), skip using OEM software |

| Distilled Water | $10.00 | 4 gallons, from grocery store, do not use tap water |

| Algae Biocide | $5.49 | https://smile.amazon.com/gp/product/B001D4TNH8 |

| dawn dish soap | 1/4 ounce | |

| Air pump | $30.00 | https://smile.amazon.com/gp/product/B07919S51M |

| Air hose | $6.00 | https://smile.amazon.com/gp/product/B0002563MW |

| $386.08 | ||

| Optional Upgrades | ||

| Cohesion3d Controller | $140.00 | |

| Lightburn software | $40.00 | 1 year support |

| A4988 Drivers | $10.00 | Z & A Axis |

| USB Cable | $10.00 | Better quality than what came with K40 |

| 10 turn potentiometer, 5k | $11.00 | https://smile.amazon.com/gp/product/B07D8KN6QW |

| Digital volt meter | $2.40 | https://smile.amazon.com/gp/product/B00YALV0NG |

| 24v power supply | $20.00 | https://smile.amazon.com/gp/product/B01CS5G8J6 |

| Coolant Temp and flow sensor | $15 | https://smile.amazon.com/gp/product/B01A0HIEFU |

| $248.40 | ||

| Z Table (optional) | Will require controller upgrade to Cohesion3d or ramps for motorized version, there are manual versions on thingiverse | |

| GT2 pulleys 20t 8MM bore | $10.00 | https://smile.amazon.com/gp/product/B07BVC3NXK |

| GT2 pulleys 20t 5MM bore | $9.00 | https://smile.amazon.com/gp/product/B01IMR6OR0 |

| GT2 idler pulley 5mm bore | $10.00 | https://smile.amazon.com/gp/product/B07D9GBWVS |

| 1220 mm GT2 idler belt loop | $19.00 | https://smile.amazon.com/gp/product/B018HMU9NU |

| 8mm tnut 4 start | $10.00 | https://smile.amazon.com/gp/product/B078N8QD6C |

| Lead screw 8mm 4 start | $14.00 | https://smile.amazon.com/gp/product/B0728FT5TZ |

| Nema 17 83 oz/in stepper motor | $14.00 | https://smile.amazon.com/gp/product/B00PNEQKC0 |

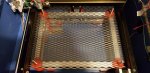

| Perforated Aluminum Sheet | $25.00 | https://smile.amazon.com/gp/product/B07CKJJSLP |

| 3/4" x 3/4" square tubing 2@36" | $25.00 | Lowes |

| 3d printed parts | https://www.thingiverse.com/thing:3156674 and motor mount from https://www.thingiverse.com/thing:3158394 or just build the second thing | |

| $136.00 | ||

| Rotary (optional) | Can swap motor plug with Y axis plug or upgrade to a Cohesion3d or Ramps controller | |

| 3d printed parts | https://www.thingiverse.com/thing:3174149 | |

| threaded rod | $4.00 | Lowes |

| GT2 timing belt | $7.00 | https://smile.amazon.com/gp/product/B074W229W1 |

| GT2 pulleys 20t 8MM bore | $10.00 | https://smile.amazon.com/gp/product/B07BVC3NXK |

| GT2 pulleys 20t 5MM bore | $9.00 | https://smile.amazon.com/gp/product/B01IMR6OR0 |

| Nema 17 83 oz/in stepper motor | $14.00 | https://smile.amazon.com/gp/product/B00PNEQKC0 |

| O-rings | $11.00 | https://smile.amazon.com/gp/product/B00595Y8WM |

| $55.00 |