I have the same problem with my 1.5 hp collector and 4 inch tubing but I am not certain the problem is flow. Mine seems to suck the fine dust down (or most of it) through the thought because I notivce a huge difference in air quality with and without the dc if I'm doing a lot of cuts. So what I think is happening is the lightest dust flows to the dust port but the heavier particles just fall down the bottom before they make it to the port. I heard 2 ways to help this problem.

I have not done either because I have not had time.

My theory is

the air flow in my saw cabinet is wrong. A larger pipe diameter and more powerful DC will not help if the air flow from the cabinet is not coming from the correct place. Other than the throat plate the there is no other vent for air to be pulled from except the louver slots in the access door. But those on the wrong side in my opinion. They really need to be opposite the dc port , up high, so air will be pulled across the falling sawdust. thats why only light dust gets out with air pulled through the throat. Much of the air is being sucked through the louvers which doesn't help because its just pulling air into the door and down to the dc port. So I was planning on blocking the louvers and putting an air port on the opposite wall. Basically cutting a 3" hole into the cabinet to start. I wand air flow down through the float and across the blade area where the dust is falling. thats why I'd start with a 3" hole.

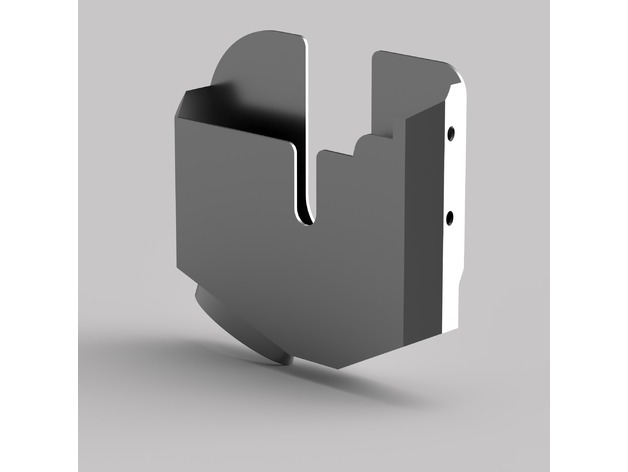

My other idea was putting a plate with a 4" hose directly under the saw blade and have the hose in the cabinet attach to the dc port in the door with a little extra flex hose so I can open the door just enough to put the hose on and off. Then dust falls right where the dc hose is and has little choice but to get sucked out. I made a cardboard box version but it has only been used under my router table to catch falling dust when I am doing routing that covers the bit so the dust only falls and doesn't go through my fence. It actually works really well for a cardboard and tape build. Just used it and it really helps a lot. I attached a picture. maybe build one and try it in your saw.its simple and cheap being cardboard just throw it away if you don't like it lol. But I bet it will solve the problem.