- Messages

- 12,169

- Location

- Constantine, MI

I hope that I do a better job of chronicling this build than I usually do.  (Maybe Glenn can prod me occasionally if my updates are not as frequent as should be.)

(Maybe Glenn can prod me occasionally if my updates are not as frequent as should be.)

I'll start on this late this week. It is a custom designed game table for a return customer. He wanted to have it be in the same family as the Limbert table I did for him a little while ago.

In addition, he has already purchased a pair of antique chairs that will be used at this table so some detail from them needed to be carried over to the tables design as well. I chose the upside down hearts seeing as they were both prominent and rather unique. (Just visible on the front stretcher of the chair on the right)

This is truly a custom piece as I have scanned hundreds of game tables on line and there is nothing like it available. This is definitely the most challenging build I have attempted to date. I usually shy away from curves. There are also some engineering challenges, mostly in the swing out compartments and the lazy susan top. Incorporating these requires a very specific order of assembly. Everything has to be done in turn.

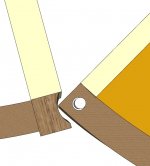

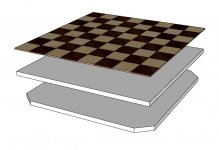

The drawings are a bit rough, but they get the point across. I'm going to go with bent lamination for the apron. 1/8" veneers cold bent around an MDF form. No steam. My research, and some quick testing here in the shop, indicates the QSWO can handle the bend without breaking. I'll use polyurethane glue as, it is my understanding, it will not 'creep' when released from the forms. That means I don't have to compensate for spring back. I hope. The chess board will be 1/8" veneers laminated to a 1" MDF substrate (two 1/2" sheets laminated).Here's the overview

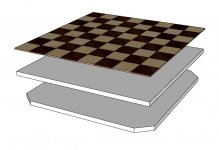

The chess board will be 1/8" veneers laminated to a 1" MDF substrate (two 1/2" sheets laminated).Here's the overview

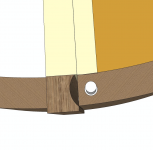

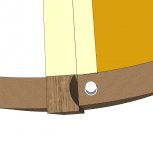

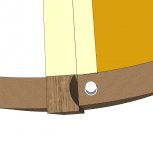

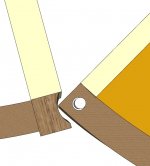

The swing out compartments are meant to be 'hidden'. So no visible hardware and the gaps need to be as small as possible. I've not figured out what type of 'catch' to use yet, but I did find a few ideas on the web for hinging the compartment. This drawing shows the basic idea, though I will likely be moving the hinge point in a little to minimize the 'cutout' that allows the end of the drawer face to swing in.

Finally, the lazy susan. I want the motion to be smooth and there should be no 'rocking' of the table top. If someone leans on the edge of the table I don't want the other side to lift. So, I'm thinking of going with a commercial grade 24" ball bearing mechanism that will support the top almost at its perimeter - the top is 27". This presents two more challenges. Since the mechanism is about 9/16" deep I will have to provide a groove in the underside of the table about 1/2" deep for the susan to sit in which will keep the gap between the top and apron to about 1/16". This then intrudes into the space for the chessboard. This is why I will use two 1/2" pieces of MDF for my substrate as I can cut off the corners of the lower piece to clear the susan.

I'm aiming for about 6 to 8 weeks start to finish. I'm hoping for less, but I know that there are challenges lurking in the shadows just wating to jump up and bite me in the rear.

I'll start on this late this week. It is a custom designed game table for a return customer. He wanted to have it be in the same family as the Limbert table I did for him a little while ago.

In addition, he has already purchased a pair of antique chairs that will be used at this table so some detail from them needed to be carried over to the tables design as well. I chose the upside down hearts seeing as they were both prominent and rather unique. (Just visible on the front stretcher of the chair on the right)

This is truly a custom piece as I have scanned hundreds of game tables on line and there is nothing like it available. This is definitely the most challenging build I have attempted to date. I usually shy away from curves. There are also some engineering challenges, mostly in the swing out compartments and the lazy susan top. Incorporating these requires a very specific order of assembly. Everything has to be done in turn.

The drawings are a bit rough, but they get the point across. I'm going to go with bent lamination for the apron. 1/8" veneers cold bent around an MDF form. No steam. My research, and some quick testing here in the shop, indicates the QSWO can handle the bend without breaking. I'll use polyurethane glue as, it is my understanding, it will not 'creep' when released from the forms. That means I don't have to compensate for spring back. I hope.

The chess board will be 1/8" veneers laminated to a 1" MDF substrate (two 1/2" sheets laminated).Here's the overview

The chess board will be 1/8" veneers laminated to a 1" MDF substrate (two 1/2" sheets laminated).Here's the overview

The swing out compartments are meant to be 'hidden'. So no visible hardware and the gaps need to be as small as possible. I've not figured out what type of 'catch' to use yet, but I did find a few ideas on the web for hinging the compartment. This drawing shows the basic idea, though I will likely be moving the hinge point in a little to minimize the 'cutout' that allows the end of the drawer face to swing in.

Finally, the lazy susan. I want the motion to be smooth and there should be no 'rocking' of the table top. If someone leans on the edge of the table I don't want the other side to lift. So, I'm thinking of going with a commercial grade 24" ball bearing mechanism that will support the top almost at its perimeter - the top is 27". This presents two more challenges. Since the mechanism is about 9/16" deep I will have to provide a groove in the underside of the table about 1/2" deep for the susan to sit in which will keep the gap between the top and apron to about 1/16". This then intrudes into the space for the chessboard. This is why I will use two 1/2" pieces of MDF for my substrate as I can cut off the corners of the lower piece to clear the susan.

I'm aiming for about 6 to 8 weeks start to finish. I'm hoping for less, but I know that there are challenges lurking in the shadows just wating to jump up and bite me in the rear.

Last edited: