Should be fun. Is that the 10'x20'?

Maybe a nice new little electric screwdriver is in your future? That was sort of mandatory kit back in the 90's when assembling a bunch of PC cases (plus bandaids for the break cut sheet metal they all used back then).

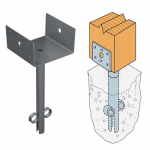

The last greenhouse I built.. almost 20 years ago (sheesh) I put on a treated 4x4 footing set on concrete piers with the top of the 4x4s at ground level on the outside. I bolted the 4x4s to the anchors and then set it all up shimmed the 4x4s level and poured the concrete into the predug holes for the pier. Made it easy to level anyway, and I got another 4" of head room from digging out the inside to the depth of the 4x4s (I left the outside buried to seal it up). Looks like yours is taller though so the extra height might not be quite as helpful

One other note: imho a venting kit and preferably an automatic venting kit is almost mandatory with these. I'm guessing you probably already have something in mind, but it can get WAY to hot in a greenhouse like that way faster than you'd think.