- Messages

- 16,936

- Location

- Reno NV

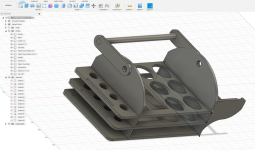

Going to head back to the drawing board with this one. I wanted a little caddy for taking tools and equipment out to the blackstone so drew this up this morning and cut it up on the cnc.

I don't intend for it to carry food out, but condiments, and other stuff would be nice.

I think I might actually delete all my fusion 360 files associated with this, lol.

(But I will use it till I make a replacement.)

- For starters, it's just way too big.

- I'm not happy with the assembly method.

- It's a bit ugly.

- The plywood is pretty low quality

- The design is, just a bit off.

I don't intend for it to carry food out, but condiments, and other stuff would be nice.

I think I might actually delete all my fusion 360 files associated with this, lol.

(But I will use it till I make a replacement.)

(Seriously, one Christmas we decided the gift we'd give each other was a new Dyson vacuum...purchased after Christmas to take advantage of the after-Christmas sales.)

(Seriously, one Christmas we decided the gift we'd give each other was a new Dyson vacuum...purchased after Christmas to take advantage of the after-Christmas sales.)