Bill Satko

Member

- Messages

- 3,397

- Location

- Methow Valley

Amen to that. I don't bother trying to pick up curlies with the vac although I use them for many other tasks. A broom and one of those amusement park style dust pans is my preferred weapon for that sort of stuff.I didn't know such things existed. Unfortunately, shaving tend to clog vacuums and besides, mine is much quieter.

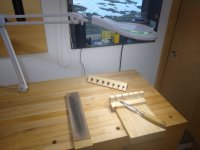

Good point, I may have to add a slot. Thanks!Just an observation. With long tools like chisels and rasps I like an open slot so I don't have to lift the tool the full length to remove it.

This also lets me put other things above the long tools while still being able to get them in and out easily.

Glenn saved me from making a real mistake with some of my tool holders with the above advice. Luckily I was easily able to modify the 3 holders I was in the process of making. All the others I had made previous, all had open slots except the one I made for my plane floats. Some of those floats are really long and would have been difficult to pull out without an open slot and would impact anything I tried to install above it.Just an observation. With long tools like chisels and rasps I like an open slot so I don't have to lift the tool the full length to remove it.

View attachment 119611 . View attachment 119612

This also lets me put other things above the long tools while still being able to get them in and out easily.

I know, right? Bill's shop accessories show more craftsmanship and skill than pretty much any woodworking I've ever done.Now you're just showing off.

When I first started making these, I thought I would just bang them out. I mean they are just shop "furniture". But as I got going, I could not help and do the best job I could. And as I progressed it became really apparent that the skills I was honing would become valuable when I was making some REAL projects again. I have probably used my chisels more in the last month than I did in the previous 5 years. And I am using them constantly everyday. The same goes for my floats, rasps and brace. The hand plane and handsaw work was always something I did on a very regular basis when I had a shop, but I also continue to improve in these areas. I don't think you ever stop improving your techniques.Now you're just showing off.

So true. I am just starting to feel comfortable with the basics again after a break. The holders look great. If you're like me you will pause every now and again over time and think about how glad you are that you took the time to make custom holders. Such a simple thing. But when you reach for your tools often and find them easy to get your hands on . . .And as I progressed it became really apparent that the skills I was honing would become valuable when I was making some REAL projects again.