glenn bradley

Member

- Messages

- 12,070

- Location

- SoCal

I'm sure most of us on here know how to do this or have at least seen an article on it. Never the less, I am all finished picking up after the last project and this is on my list. I use a selection of tools based on the size of the bit. This bit is a 1" so everything should be pretty easy to see.

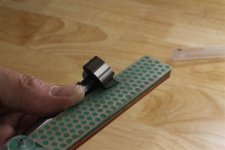

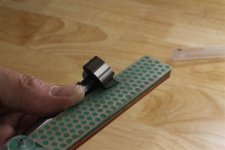

I use a paddle of some sort (diamond file, credit card, honing stick, whatever) to do the faces of the cutter.

I am holding this with one hand and snapping the pic with the other so you can see the rear of the face is slightly elevated. DO NOT do this. You want the face flat against the abrasive. Give an equal number of strokes to each face. I use a fine and an extra fine.

You will feel a bit of a wire edge as a telltale of your progress. I use a smaller file for the tooth in the rim. Your bit may not have a tooth or it may have many teeth. I use this same tool to refresh the center spur.

You want that leading edge nice and sharp.

For the rim I use a stone. The smaller the bit, the smaller the stone. It is easy for me to make a mistake on a smaller bit with a large stone and make a bunch of recovery work for myself.

I approach the bit like so for the inner edge of the rim.

I use a rolling motion to pass the full length of the inner face of the rim past the stone. Again, make an equal number of passes on each face.

I've almost got it. You can see a bit of area that I have not gotten to at the very edge of the rim. Once you are all sharpened up your bits will cut like new again

I use a paddle of some sort (diamond file, credit card, honing stick, whatever) to do the faces of the cutter.

I am holding this with one hand and snapping the pic with the other so you can see the rear of the face is slightly elevated. DO NOT do this. You want the face flat against the abrasive. Give an equal number of strokes to each face. I use a fine and an extra fine.

You will feel a bit of a wire edge as a telltale of your progress. I use a smaller file for the tooth in the rim. Your bit may not have a tooth or it may have many teeth. I use this same tool to refresh the center spur.

You want that leading edge nice and sharp.

For the rim I use a stone. The smaller the bit, the smaller the stone. It is easy for me to make a mistake on a smaller bit with a large stone and make a bunch of recovery work for myself.

I approach the bit like so for the inner edge of the rim.

I use a rolling motion to pass the full length of the inner face of the rim past the stone. Again, make an equal number of passes on each face.

I've almost got it. You can see a bit of area that I have not gotten to at the very edge of the rim. Once you are all sharpened up your bits will cut like new again