OK, I will jump in here.

Woodworking at it's core. Hmmmm, OK?

If you are getting to know me, you should realize that I am into woodworking - BUT - with more added in. I think most of us are.

My project has involved cutting a little steel, and some aluminum. It is with the intention of creating an environment where I can do woodworking on my CNC machine.

As a part of upgrading my CNC machine I NEED a little cabinet built into the base. THAT, is somewhat conventional. somewhat I say. I will also be doing some painting and a little more steel working, but the cabinet is mostly wood.

Truly, I am not much interested in building shop cabinets or shop tools, but I do build what I need to have.

I have several objectives for this cabinet

1) Make it a sealed cabinet, mostly for the water tank - to keep even the fine dust out.

2) Make the entire cabinet easily removable - in the event I need the vertical clamping space

3) Functional and WELL organized with Kaizen foam drawer inserts

4) Good drawers do NOT need to be dovetailed

5) It needs to "show off" the CNC machine.

This is the area that the cabinet will fit into

I will do some really nice painting of the white machine base, and some really nice staining of the Oak inserts and drawers

I used the machine to cut out the cabinet facing and drawer openings. Backside is rabited.

Cross pieces

Cabinet sides and drawer supports

Borg Soft Close slides - nothing fancy - functional - a little "show off"

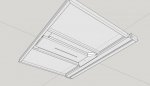

WAY - WAY - WAY overkill here, but fun to make.

I had a sassy smirk on my face making this.

It is a cross member that will span the metal frame of the machine to support the back of the cabinet. It is easily removable. It is a GLUELAM. My design, my build. It is 4 layers of 3/4 sanded ply from Lowes, carefully CNC cutout. I sanded and carefully glued and clamped with my wooden parallel cabinet clamps. There are no voids. I gave is 3 coats of poly.