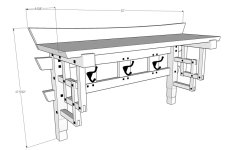

OK, I'm way late to the party and still not happy with the outcome, but this will have to do for now. I may completely start over at some point and just re-use the hardware. My design constraints were A) make something SWMBO would approve of, and B) spend as little money as possible. We only have one place in the house where a coat rack would fit, and it was already occupied with this:

I wanted to build something with more capacity since the one we were using was always overfilled, with multiple things on each hook.

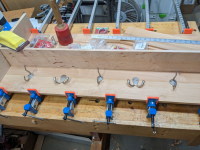

My wife is into dogs and birds. I happened to find some hardware on sale at Hobby Lobby that checked both those boxes, and she liked it. I also figured I could incorporate the plaque from the old hanger into the new one.

My stash of decent lumber is pretty meager and I didn't have enough hardwood to do the project, so I bought some rough fence planks from Lowe's. That proved to be a big mistake, because within a couple of days the wood had warped, cupped, and twisted so badly it was unusable. I thought I might be able to make it work, but after dry clamping it I realized it was hopeless. (I could have planed it flat, but it would have end up less than 1/4" thick.)

My fallback plan was to use some 1/2" cabinet grade plywood that was left over from a project I did for my sister a few years ago.

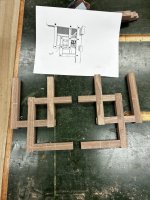

I needed to edge join two pieces to get the size I wanted and since it was plywood, I used some scrap to help add a bit of strength.

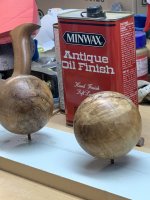

Sorry, no pics of the rabbet I cut to accommodate the shelf. I wanted to hide the joint on the backboard part, so I decided paint was the best way to cover it up. I had planned to go with a rustic/weathered paint job where I sanded lightly through the paint in a few places, but I wanted the wood under the paint to be dark brown, so I sanded the stained side of the plywood and used Transtint dye over it as well as the edges of the wood. Since both sides of the shelf would be visible, I also dyed the unstained side of that. I picked up a matte off-white acrylic paint that seemed like it would give me the desired look. Problem was, the Transtint bled through the paint almost as fast as I could apply it.

My brain finally woke up and I used some dewaxed shellac to seal up the stained paint, and applied another couple of coats of paint over it. That finally handled the bleeding.

Next, I installed the dark metal hardware and within minutes my wife and I both agreed it looked bad. There was too much contrast between the painted wood and the hardware. (Sorry, I was so ashamed I didn't even bother taking photos. Trust me, it sucked.) So I pulled off all the hardware, masked off the plaque (which is glued on), and sprayed a flat bronze/gold paint that seemed like it'd work. Well, it didn't. It's better than the off-white, but it still looks like something Holly Hobby would make at craft class and show off to her housewife friends.

Anyway, it is what it is (for now).

That's my story and I'm stickin' to it.

My brain finally woke up and I used some dewaxed shellac to seal up the stained paint, and applied another couple of coats of paint over it. That finally handled the bleeding.

My brain finally woke up and I used some dewaxed shellac to seal up the stained paint, and applied another couple of coats of paint over it. That finally handled the bleeding.