- Messages

- 11,436

BTW Glenn, on the first table I did, I put the 45 on the fronts of the legs for the hard line, on the band saw like Sam would do. Since then I put a 45 degree bit in the router and use the router, it's much easier to control.

Since then I put a 45 degree bit in the router and use the router, it's much easier to control.

Sam said he could rough out a table in a half a day but it would take "the boy 2 weeks to finish it"..Amen. Its cool to watch Sam do that but, I did it a bit on the mock-up and didn't feel very cool at all. I'm going with a more sculpted look. Kinda trying to make this a "Maloof-like" table, not a Maloof table (as if I really could

). During my visit, Larry White mentioned that it takes him about 3 weeks to sand a lowback chair. I don't know that I have 3 weeks of sanding on the same project in me

.

.

.

Curious about your shop made depth gauge. Is there another post about how you made it and how you use it?

Hi Glenn,

I'm new here but I wanted say how much I'm enjoying your progress on the table. I'm keen to attempt a Maloof style pedestal table myself and your posts (plus Don's posts) have given me a great head start.

Please keep them coming

Cheers,

Geoff

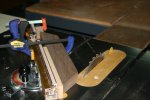

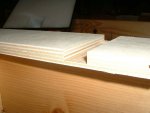

Glenn, which dado set do you use ?. your cuts look almost perfect. Every set i've used leaves those little "bat ears" on the bottom of the cut.

.

.

.

.Looks good so far Glenn, are you gonna put the hardline/soft line on the legs like Sam did ?